Many of these optical instruments rely on multiple sources and detectors. In addition, mechanical constraints are always present, especially on newer systems that incorporate a larger number of instruments onto the spacecraft.

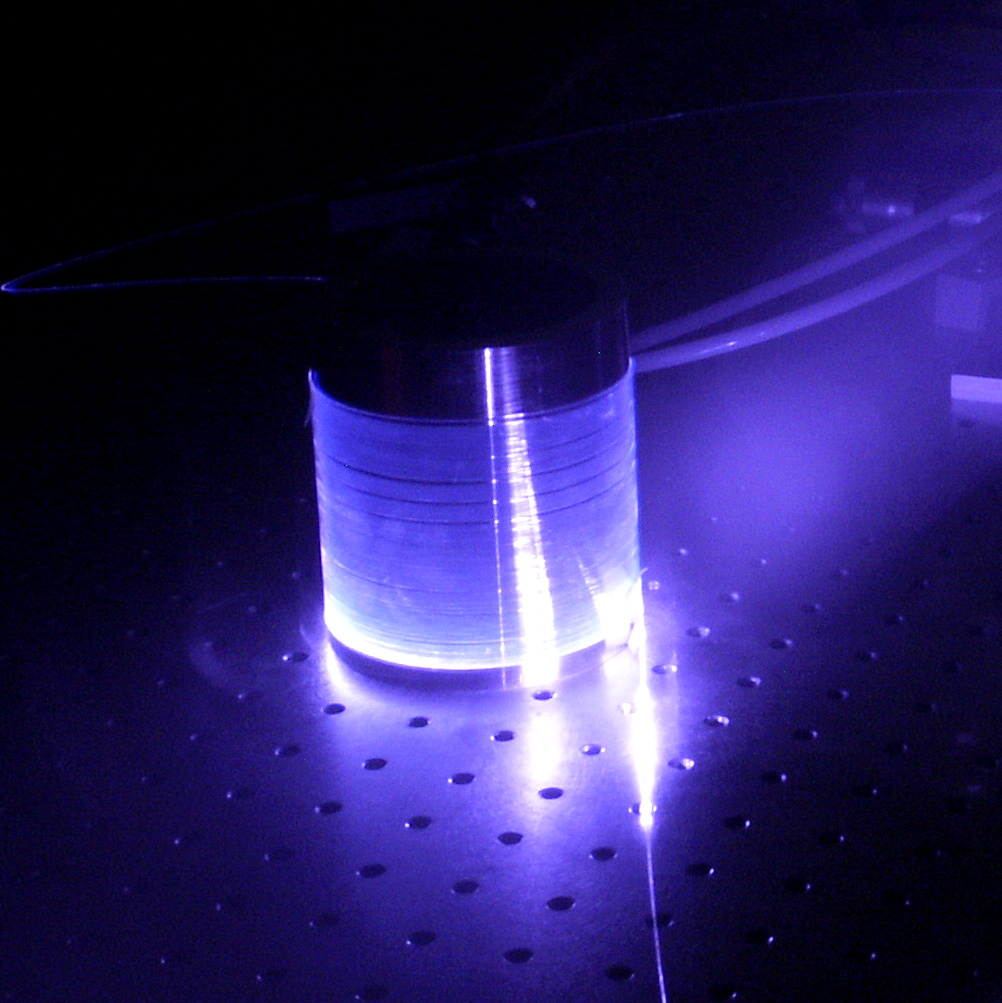

Exterior components also experience higher radiation levels, which necessitates adding shielding, further increasing weight. Thermal management requires heating and cooling to maintain desired temperatures, which adds weight and uses power. Exterior components experience large thermal changes during flight as they transition from facing toward the sun to facing away from it. This configuration presents many challenges for the spacecraft design. The transmission system would comprise a laser and collimation optics to launch the light, along with a receiver telescope and detector to collect the optical signal. A traditional optical system would use transmission and detection systems mounted on the exterior of the spacecraft. All of these systems require high optical power laser pulses for accurate detection of transmitted or reflected signals. Examples include LIDAR systems for ranging, autonomous docking systems, and optical communications between satellites and from satellites to ground-based systems. Lasers exhibiting high peak power pulses are used in a wide range of spaceflight applications. We will also discuss the proper methods for launching the laser pulses into the fiber to avoid damage and how this is being implemented for current spaceflight missions. In the current study, we will review the causes of fiber damage during high-power injection and discuss our new manufacturing procedures that overcome these issues to permit fiber use with high reliability in these applications. Typical fiber optic termination procedures are not sufficient for injection of these high-power laser pulses without catastrophic damage to the fiber endface. Coupling the laser energy into a fiber optic cable allows the laser to be relocated to a more favorable position on the spacecraft. Future applications will require multiple lasers located close together, which further complicates the design.

This presents challenges for thermal management, radiation resistance, and mechanical design. Due to the high optical power needed, the laser has to be located on the exterior of the satellite or coupled through a series of free space optics. Lasers with high peak power pulses are commonly used in spaceflight missions for a wide range of applications, from LIDAR systems to optical communications.

0 kommentar(er)

0 kommentar(er)